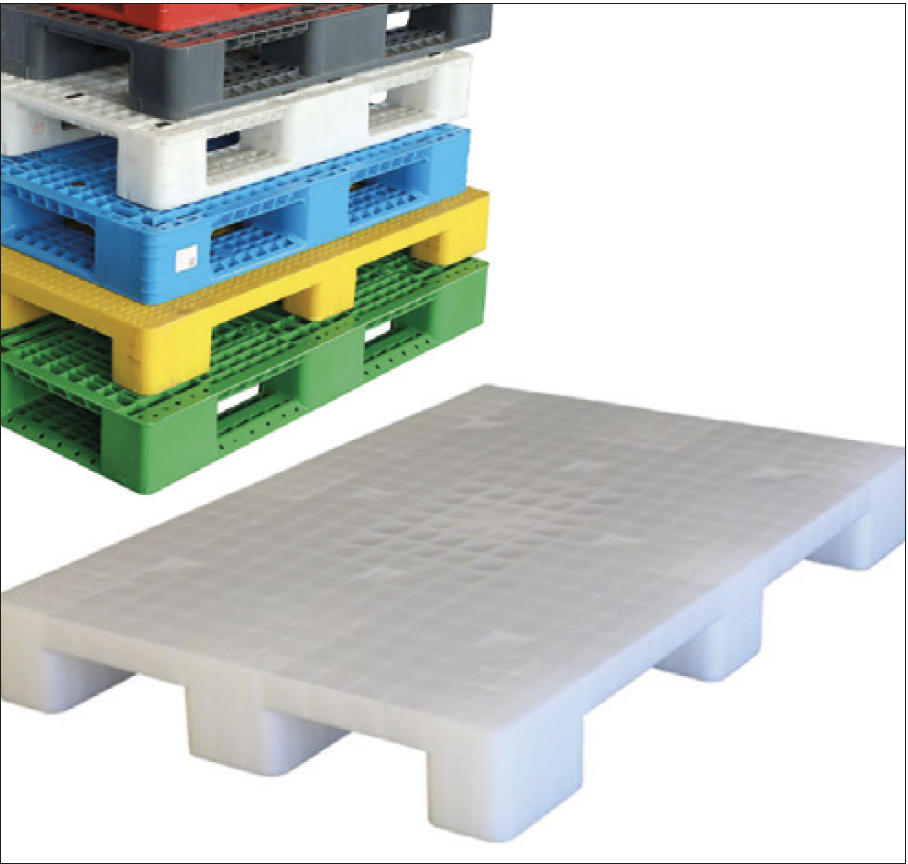

High-density polyethylene is a suitable material for various shaping methods such as extrusion, injection molding, powder coating, film blowing, and rotational molding. HDPE injection grades are particularly preferred for components that require high mechanical strength. Thanks to their resistance to environmental factors, they provide long-term durability even under outdoor conditions.

| Property | Test Method | Unit | Typical Value |

|---|---|---|---|

| Physical Properties | |||

| MFI (190°C / 2.16Kg) MFI (190°C / 2.16Kg) | ASTM D 1238 | g/10 min | 7.2 |

| MFI (190°C / 5.0Kg) MFI (190°C / 5.0Kg) | g/10 min | 21.5 | |

| Density Density | ASTM D 1505 | g/cm³ | 0.960 |

| Formulation | |||

| Anti Oxidant Anti Oxidant | — | √ | — |

| UV Stabilizer UV Stabilizer | — | √ | — |

| *Mechanical Properties | |||

| Flexural Modulus Flexural Modulus | ASTM D 790 | MPa | 1250 |

| Tensile Strength at Yield Tensile Strength at Yield | ASTM D 638 | MPa | 31 |

| Elongation at Break Elongation at Break | ASTM D 638 | % | 1000 |

| Charpy Impact Strength Charpy Impact Strength | ASTM D 256 | Kj/m² | 11 |

| Hardness Shore D Hardness Shore D | ASTM D 2240 | - | 68 |

| ESCR ESCR | ASTM D1894 | hr | 12 |

| Thermal Properties | |||

| Vicat Softening Temperature Vicat Softening Temperature | ASTM D 1525 | °C | 125 |

| Melting Point Melting Point | ASTM D2117 | °C | 132 |

The above data are typical laboratory averages and are intended as a guide only.